Color

Dyeing

During the patented computer-controlled “deep dyeing process” the polymer matrix is penetrated by UV absorbers and/or colour pigments. In this way the films are directly tinted and not merely coated with colour, thus attaining the best possible colour stability and resistance to abrasion.

Vacuum

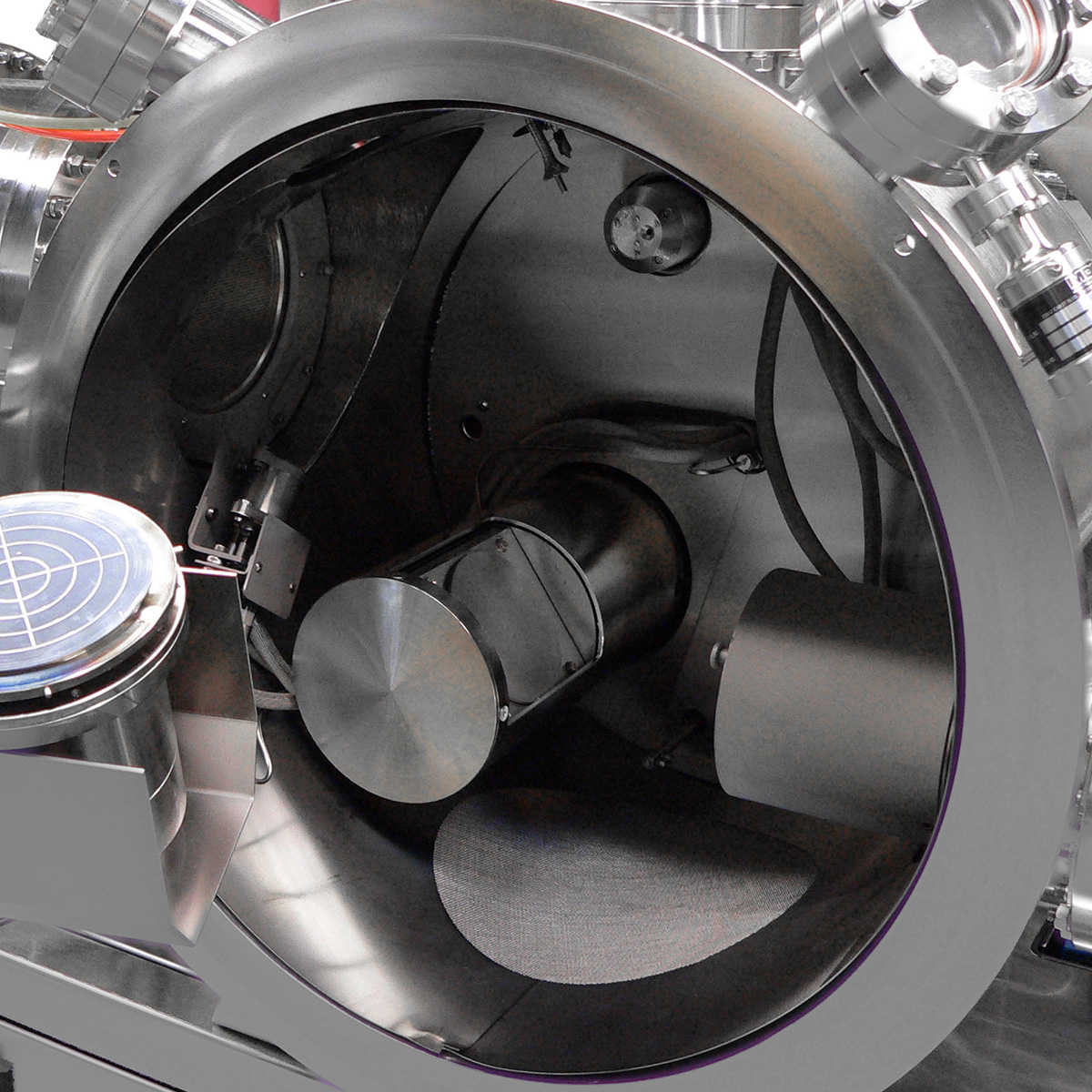

Metalizing

Aluminium is heated in a high vacuum and vapour plated onto the film. The thickness of the metal layer is controlled to ensure unsurpassed visual quality.

Sputtering

During the sputtering process (vacuum coating by cathodic Sputtering) metal atoms are introduced into the surface of the film. Alloys and metals such as gold, silver, tin, chromium nickel, copper, titanium or stainless steel are processed using this procedure.

Coating & Laminating

The manufacturing processes used to produce security film at the CPFilms plants in Virginia and the United Kingdom rely heavily on expert coating and laminating. The coating and laminating department has the ability to produce multi-layer security and combination solar films in roll widths up to seventy-two inches. The lamination of the various layers as well as the application of mounting adhesives is performed in this department. This phase of the process is critical to the performance and longevity of the product.